Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and

احصل على السعر

2021-8-31 Iron ore processing is also essential to providing a high-quality raw material for the metallurgical production chain. This article will take you to learn iron ore processing. 1.

احصل على السعر

In India, where iron ore processing is one of the major industries, the generation of tailings is estimated to be 10-25 % of the total iron ore mined, amounting to 18 million tons per year (Das

احصل على السعر

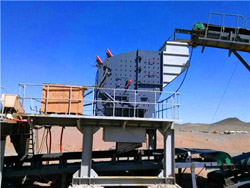

Iron Ore Crushing Processing Kefid Machinery. 2018831Iron Ore Crushing Processing Iron ore is an important raw material for the iron and steel producers It exists in nature with pounds state,

احصل على السعر

Iron Ore Processing,Crushing,Grinding Plant Machine . Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be

احصل على السعر

Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust. Viable forms of ore contain between 25% and 60% iron. Ore greater

احصل على السعر

Magnetite Iron Ore Processing. Because of the strong magnetism of magnetite, the extraction of iron from magnetite is weak magnetic separation technology. The magnetite iron ore

احصل على السعر

2021-10-23 what is iron ore lumps and iron ore fines. what is the diference iron ore fines less than 6mm sized ore size 5mm to 20mm lump ore size 10mm to 40mm iron ore fines are

احصل على السعر

2020-5-20 4 Siderite Ore Extraction Method. Siderite is one of the common iron ores. After the accumulation of production practice, there are 4 commonly used beneficiation processes:

احصل على السعر

The grade of iron ore refers to the mass fraction of iron element in iron ore, say, the iron content. For example, if the grade of iron ore is 62, the mass fraction of iron element is 62%. Through crushing, grinding, magnetic separation, flotation separation and re-election, the iron can be selected from the natural iron ore. Iron ore

احصل على السعر

Iron Ore Processing,Crushing,Grinding Plant Machine . Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore Iron Ore

احصل على السعر

2017-10-23 The raw materials mix or “charge” enters the furnace from the top and hot air is blown or blasted from the bottom causing the coke to burn and the oxygen to combine with carbon in the coke to form carbon monoxide. Now,

احصل على السعر

Iron ore is an important raw material for iron and steel production enterprises. After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore). It is the mineral aggregates

احصل على السعر

Iron Ore Processing,Crushing,Grinding Plant Machine Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization.

احصل على السعر

2022-6-13 The iron ore processing and production process refers to the production process in which the mined iron ore must be processed and produced by various operations to obtain concentrates that meet the smelting requirements. Mainly include: ore crusher crushing and vibrating screen screening, ball mill grinding and classifier classification; mineral separation,

احصل على السعر

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing. The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via

احصل على السعر

iron ore processing dry or wet plants Crushing plant for wet iron ore and clay Oct 21 2016 comApr 3 2014 Run of mines ores after dry or wet sizing if it . Crushing plant for wet iron ore and clay Oct 21 2016 Crushing plant for wet iron ore and clay A Mineral Processing Testwork Warning Don 39 t dry clay ores or .

احصل على السعر

2018-10-23 S + O 2 → SO 2. 4 P + 5 O 2 → 2 P 2 O 5. Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of

احصل على السعر

2009-1-1 The importance of comminution test works originates from the high level of energy consumed in the processing chain to grind the ore to achieve a desirable particle size, liberation, and high iron

احصل على السعر

For obtaining iron, ore concentrates from low-grade ore various processing routes of gravity separation, flotation and magnetic separations are in practice through out the world and India too. More about Iron Ore Crushing & Screening Iron Ore Grinding Iron Ore Grinding Process is an optional process, which prepares for the iron ore beneficiation.

احصل على السعر

The first stage: crushing & screening three stage closed-circuit crushing Large pieces of iron ore are uniformly sent to the jaw crusher or coarse crushing mobile station by the vibrating feeder for coarse crushing; the coarsely crushed iron ore is screened by the vibrating screen and sent to the single-cylinder hydraulic cone crusher for processing Medium crushing: The iron ore material

احصل على السعر

2022-2-17 Iron Ore Processing 2020 New Type Low Price Jaw Crusher. Iron ore processing technology the iron ore beneficiation crushing production line has high degree of automation, high breaking rate, low operating cost, energy saving and environmental protection, and fine grain size. the production line is mainly based on the actual material size and the customers requirements

احصل على السعر

2017-10-23 The raw materials mix or “charge” enters the furnace from the top and hot air is blown or blasted from the bottom causing the coke to burn and the oxygen to combine with carbon in the coke to form carbon monoxide. Now,

احصل على السعر

2011-10-15 Iron ore processing can be a procedure that contains explosions, shoveling, moving, crushing, grinding, pelletizing etc. Iron ore processing provides a range of coarse sizing that may produce material in 24-inch to .0017-inch

احصل على السعر

processing of iron ore crushing or of or iron or ore 2019-07-18T06:07:36+00:00 : Iron Ore Mining Application Cone crushers . Jan 18, 2011 Contact us:

احصل على السعر

2019-11-15 4 Siderite Ore Extraction Method. Siderite is one of the common iron ores. After the accumulation of production practice, there are 4 commonly used beneficiation processes: Gravity separation, Strong magnetic separation, Strong magnetic separation-flotation, Magnetization roasting-weak magnetic separation. 2022-03-31 12:03:04.

احصل على السعر

2018-10-23 S + O 2 → SO 2. 4 P + 5 O 2 → 2 P 2 O 5. Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of

احصل على السعر

iron ore processing dry or wet plants Crushing plant for wet iron ore and clay Oct 21 2016 comApr 3 2014 Run of mines ores after dry or wet sizing if it . Crushing plant for wet iron ore and clay Oct 21 2016 Crushing plant for wet iron ore and clay A Mineral Processing Testwork Warning Don 39 t dry clay ores or .

احصل على السعر

2016-5-26 The technology aims to improve the recovery of iron ore still contained in wastes or low grade ROM making it possible to obtain iron ore concentrate with 68 per cent iron, and ultimately providing

احصل على السعر