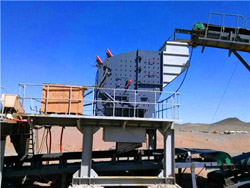

Crushing Process In A Cement Plant. Cement Crushing Grinding Plant In cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc. Limestone is the largest amount of raw material during cement

احصل على السعر

cement crushing process, cement crushing equipment, cement The crushing of cement aims at producing uniform size particles by crushing, grinding and sorting. The cement crushing process is a multilevel process and it can be concrete crushing how the process goes Iron Ore Crushing and Screening used for Mining Process Flow

احصل على السعر

We supply all types of crushers and crushing equipment to be used in cement plants. Portable Concrete Crusher There are two types of concrete plant: ready mix plants and central mix plants. Portable concrete plants or Mobile concrete crusher is one of main products. types of cement crusher, wikipedia Grinding Mill China

احصل على السعر

Aug 25, 2020 There are three steps of the high-temperature system: Drying or preheating, calcining, and sintering. The calcining is the core part of the clinker production; the raw meal is weighed and sent into preheater and cement kiln to process clinker. Grate cooler helps to cooler clinker, the cooled clinker is sent to the cement silo for storage.

احصل على السعر

2.1 One time crushing process Jaw crusher VS impact crusher 2.2 Multiple times crushing process Check the capacity by considering the nominal feed opening, closed side setting S.S.S and crusher type, then choose the reasonable equipment. If need four times crushing process, the gyratory crusher usually is the fourth crusher.

احصل على السعر

Even though the ore is reduced below 3 mm with conical and some impact crushers, this process is called crushing. The process of size reduction is defined by below conversion formula: The ore whose size will be reduced + Energy = Reduced-size ore + Sound + Heat

احصل على السعر

Nov 21, 2019 In the cement production line, limestone, clay, iron ore, coal, and other materials should be crushed. The main crushed material is limestone, there are jaw crusher, cone crusher, impact crusher, hammer crusher, and other crushers to be selected. For cement crushing plant, vibration feeder and vibrating screen will be equipped together.

احصل على السعر

Aug 30, 2012 Proportioning of raw material at cement plant laboratory Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table. Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller. Roller crushes the material to a fine powder and finishes the job.

احصل على السعر

Crusher, sieving and washing processes are performed in the crusher plant formed by the combination of many different machines. Different machines can be used during the process, as these processes vary from time to time using different machines.

احصل على السعر

Sep 27, 2019 Cement mill is another necessary cement equipment of the cement plant. After raw material crushing, cement mill plays vital role in the further cement manufacturing process. Cement ball mill, vertical cement mill, and cement roller press are common types of cement grinding plant. cement ball mill

احصل على السعر

Limestone Crushing Plant In Cement Process. Limestone crushing process types and 1000 000 tonyear limestone crushing plant for cement limestone mining process and crushing plant for the Get Price Simply complete the form below click submit you will get the price list and a ZME representative will contact you within one business day.

احصل على السعر

Crushing plant Cement industry news from Global . 20151028US: Lehigh Cement Company, part of Heidelbergcement Group, has ordered a semimobile limestone crushing plant from Hazemag for its Union Bridge cement plant The plant will process up to 2500t hour of limestone with a feed size of up to 2000mm The material is discharged by means of a Hazemag apron

احصل على السعر

In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, process of concrete crushing Gulin machine in iron ore processing plant, process of concrete crushing.

احصل على السعر

Clinker grinding stage: it adopts DPX crusher to crush plaster and cement clinker is pre-milled by roller press, hammer–mill crusher and XPCF crusher and then grinded by flour mill. In the whole process, it may be seriously abrades steel ball, liner plate, grid plate. DSMAC is also specializing in manufacturing Big Gold Teeth hammer and rotor

احصل على السعر

Cement Crushing Process Plant Manganese Crusher. Search cement crushing process plant to find your need. liming Mining and Construction Machinery is a global manufacturer and supplier, We supply full crushing and

احصل على السعر

We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining plate, grate screen, and shell.

احصل على السعر

1.2 Processing plant layout. The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h. if want a higher output, only by increasing the crushing production line. take a three crushing aggregate processing plant as an example. Feeding size of first crusher: <100mm

احصل على السعر

1500 kawasaki crusher information; how to arate crushed stone s; long range gold detector reviews in mali newest crusher; uses of silica quartz crusher; buy cement plant equipment; cone crusher operated from both sides; hammer mills manufacturers in junagadh gujarat; lab rock grinder machine price quarry machine and crusher; crusher wikipedia

احصل على السعر

Crusher, sieving and washing processes are performed in the crusher plant formed by the combination of many different machines. Different machines can be used during the process, as these processes vary from time to time using different machines. Other factors affecting this situation include the crushing plant and the size of the stones to be

احصل على السعر

May 14, 2020 Today we’ll discuss the first part- cement factory cost ( or cement plant cost). According to the data we know, the total cost of a cement plant is estimated to be US$ 17,000 to US$ 20,000 per ton. One thing to be clear, this is just an estimation, in the real cement plant building, the cement factory cost is affected by various factors

احصل على السعر

Phase IV: Calcination. The calcination is the core phase of the cement making dry process. The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant. The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinker. The high temperature in the rotary kiln

احصل على السعر

how crusher works in cement plants. 2018-4-27 in the cement plant how does crusher works Concrete . 2018-7-4 · Concrete, usually Portland cement concrete, is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens over time—most frequently a lime-based cement binder, such as

احصل على السعر

Cement crushing process in Cement plant, line crushing, For cement and line customers, the combination of and Hartl Powercrusher adds new possibilities. offers drill rigs from the smallest one handling. Go to Product Center. crushing process in cement plants ® Crusher, crushing plant group is crushing plant equipment manufaturer and

احصل على السعر

Cement Crushing Grinding Plant Dsmac. Aug 30 2012 cement manufacturing process ng and preblending 1crushing in the cement manufacturing process most material must be broken such as limestone iron ore clay and coal etc limestone is the main raw material for cement production each producing a ton of clinker needs about 13 tons of limestone more

احصل على السعر

cement crushing process in cement plant price. cement crushing process in cement plant price. raw materials of the cement plant are mostly from openpit mines and the ore size of large mines can reach 1518m in the preparation of cement raw materials we first need to crush limestone gypsum clay and other materials into proper size to facilitate

احصل على السعر

Cement Crushing Grinding Plant Dsmac. So cement is kind of cementitious material which will be of stronger hardness in water Cement mil is used for cement grinding Cement crusher is applied for cement crushing In cement mining you need to choose suitable cement grinding mill and cement crusher Production process Three stages 1. Read more

احصل على السعر

Clinker grinding stage: it adopts DPX crusher to crush plaster and cement clinker is pre-milled by roller press, hammer–mill crusher and XPCF crusher and then grinded by flour mill. In the whole process, it may be seriously abrades

احصل على السعر

how crusher works in cement plants. 2018-4-27 in the cement plant how does crusher works Concrete . 2018-7-4 · Concrete, usually Portland cement concrete, is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens over time—most frequently a lime-based cement binder, such as

احصل على السعر

Crusher Used In Cement Plants. plant cement 0400000 1 400000 tpy dry process cement plant vrm raw . 1 dual line trio jaw crusher amp incline screen plant. Read more Clinker Cement Plants Cement Plants Manufacturers. Process Flow Sheet For 100 Tons Cement Mill Crusher

احصل على السعر

1.2 Processing plant layout. The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h. if want a higher output, only by increasing the crushing

احصل على السعر

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by

احصل على السعر

1500 kawasaki crusher information; how to arate crushed stone s; long range gold detector reviews in mali newest crusher; uses of silica quartz crusher; buy cement plant equipment; cone crusher operated from both sides; hammer mills manufacturers in junagadh gujarat; lab rock grinder machine price quarry machine and crusher; crusher wikipedia

احصل على السعر

Crushing is the process of size reduction of ore. Size reduction process begins with usage of explosives at the area for production of ore. In later stages, the size reduction process performed with crushers before grinding in mills is called

احصل على السعر

Comprehensive crushing plants for increased production . Fives develops equipment and integrated plants for dry process mineral grinding applications.Our solutions are designed for high performance and flexibility,

احصل على السعر

Cement Grinding Plant. Feeding Size: ≤25mm Production Capacity: 200t/d-8,000t/d Technological Features: Crushing raw materials, pre-homogenizing materials, arranging ingredients, efficient grinding, homogenizing materials, suspending pre-heater and decomposing furnace, new type cooler, cement dosing and grinding.

احصل على السعر

Step 2 Material Grinding: At least 3 tons of materials (including various raw materials, fuel, clinker, etc.) need to be ground to produce one ton of Portland cement. According to statistics, the grinding process in the dry process of cement production line consumes more than 60% of the power of the whole plant, of which raw material

احصل على السعر

Cement Crushing Process Plant. Cement Crushing Amp Grinding Plant In Cement Production Process Cement Crusher Is Very Important Since Most Of The Raw Materials Will Have To Be Crushed Before Being Used To Process Cement Such As Limestone Clay Iron Ore And Coal Etc Limestone Is The Largest Amount Of Raw Material During Cement.

احصل على السعر

Cement crushing process in cement plant essentialgapcozaement jaw crusher processing of crushing in copper ore processing plant crushing process is the important cement production line in india the jaw crusher series mobile crusher plant is the impact jawaggregate crushing plant process scalping primary crushing secondary and tertiary.

احصل على السعر